Fully Automatic Bentonite Cat Litter Production Line with High Working Efficiency

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | Yushunxin |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $20,000.00/sets >=1 sets |

| Packaging Details: | Organic fertilizer granulating equipment compound fertilizer granules making machine disc granulator for sale <br>export package |

| Supply Ability: | 100 Set/Sets per Month |

|

Detail Information |

|||

| Product Type: | FERTILIZER | Condition: | New |

|---|---|---|---|

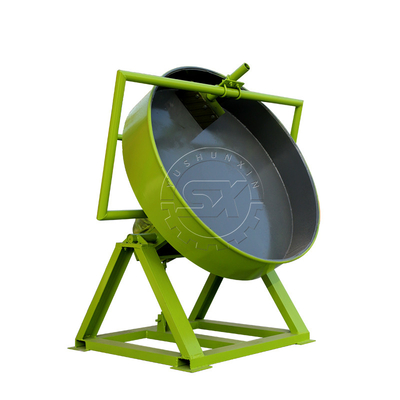

| Machine Type: | Granulator | Output (kg/h): | 1-8000 |

| Video Outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | Ordinary Product | Warranty Of Core Components: | 1 Year |

| Core Components: | Gear | Voltage: | 380V |

| Dimension(L*W*H): | Depends On Model | Weight (KG): | 2400 |

| Power (kW): | 55 | Warranty: | 1 Year |

| Key Selling Points: | Easy To Operate | Applicable Industries: | Manufacturing Plant, Fertilizer |

| Showroom Location: | None | Product Name: | Organic Fertilizer Production Line |

| Usage: | Making Fertilizer Granules | Raw Material: | Animal Manure Or Compound Fertilizer |

| Capacity: | 1-8 T/h | Function: | Granlulating |

| Final Product: | Round Ball Press Pellet | Suit For: | Fertilizer Material |

| Feature: | High Working Efficiency | Working Method: | Ball Shape Granules |

| Application: | Granules Making Machine | Port: | Qingdao, Tianjin |

Product Description

Products Description

Fully automatic bentonite cat litter production line Large tofu cat litter granulator

At present, Yushunxin supplies three main complete fertilizer manufacturing lines. They are organic fertilizer production line, compound fertilizer making line and BB manure production line. What's more, with the variety of the state of fertilizer shape, the fertilizer can be furtherly divided into granule fertilizer and the powder fertilizer, which will lead to different fertilizer manufacturing process.

Raw Materials

Agricultural waste : Straw,dregs of beans,cotto n dregs,rice bran,etc

Livestock/human waste: Mixture of poultry litter(PL) and livestock/animal/human waste,slaughterhouse waste,fish maket,urine and

dung of cattle,pigs,sheep,chicken,ducks,geese,goat,etc

Industrial waste: Wine lees,vinegar residue,manioc waste,sugar scum,furfural residue,etc

Home scrap: Food waste,bones,the roots and leaves of vegetables,etc

Mineral: Humic acid,bentonite,dolomite,etc

Others : Sludge of the rive,the sewer,etc

If you have any demand about the raw material and capacity, please contact me freely!

Agricultural waste : Straw,dregs of beans,cotto n dregs,rice bran,etc

Livestock/human waste: Mixture of poultry litter(PL) and livestock/animal/human waste,slaughterhouse waste,fish maket,urine and

dung of cattle,pigs,sheep,chicken,ducks,geese,goat,etc

Industrial waste: Wine lees,vinegar residue,manioc waste,sugar scum,furfural residue,etc

Home scrap: Food waste,bones,the roots and leaves of vegetables,etc

Mineral: Humic acid,bentonite,dolomite,etc

Others : Sludge of the rive,the sewer,etc

If you have any demand about the raw material and capacity, please contact me freely!

Specification

Model | Capacity(t/h) | Feature |

Organic drum granulation production line | 0.5-20t/h,1000-200000t/year | Raw material is power, add to 40% humidity,then make granules,dry granules. |

Organic extrusion production line | 0.5-20t/h,1000-200000t/year | Raw material is power, add to 40% humidity,then make pellets. |

Organic granulation production line | 0.5-20t/h,1000-200000t/year | Raw material is power, add to 40% humidity,then make granules,dry granules. |

Disc granulation production line | 0.5-20t/h,1000-200000t/year | Raw material is power, add to 40% humidity,then make granules,dry granules. |

Working principle

The process of organic fertilizer production line is as follows:

1.Raw material fermentation – 2 Automatic beltscale batching system —-3 Crushing, mixing — 4 Disc granulation, drum granulation, extrusion granulation —-5 Dryer, Drying Organic Fertilizer Granules—6 Cooling Machine, Cooling Organic Fertilizer Particles—–7 Screening Machine. Screening Out Qualified Organic Fertilizer Particles—–Intelligent Small Fertilizer Equipment|Intelligent Small Organic Fertilizer Production Line L-8 Coating Membrane machine, coated film granules, making the granules smoother—-9 Packing scale, automatic filling organic fertilizer granules –10 seal

Pre-sale Service:

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

4.Training periodically high qualified service technician;

5.Free CAD design: if you can provide the material, your aim capacity and your factory information, we can make a free CAD design for you.

After-sales Service:

1.Highly inspecting equipment in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3.Assisting our clients for foundation construction of equipment;

4.Dispatching engineers to install and debug equipment;

5.Training the first-line operators on site;

6.Regularly visit clients to solve production problems Providing life-long maintenance service;

7.Providing technical exchanging.

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

4.Training periodically high qualified service technician;

5.Free CAD design: if you can provide the material, your aim capacity and your factory information, we can make a free CAD design for you.

After-sales Service:

1.Highly inspecting equipment in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3.Assisting our clients for foundation construction of equipment;

4.Dispatching engineers to install and debug equipment;

5.Training the first-line operators on site;

6.Regularly visit clients to solve production problems Providing life-long maintenance service;

7.Providing technical exchanging.

FAQ

1.Are you manufacturer or trade company?

A:We are a professional manufacturer for producing fertilizer processing equipment and related machine(fermentation machines,granulator, crusher, mixer, packing, feeding machines and conveyor belt) etc.

2.How should to do if I meet some trouble while using?

A:The English manual book and video will be provide for showing how to resolve the problems, if necessary, we will dispatch our engineer to your factory.

3. Do you provide the installation service after ordering your machines?

A:As for the single machine, we provide the users instruction and operation video.

As for the production line,we provide the professional construction drawing,and arrange the engineer guide the user install the machines.Help the user train the skilled workers.

4.Can we visit your factory to see some fertilizer plant with your machine?

A:We really give every customer a warm welcome to visit our factory,and we can take the customer to visit fertilizer plants with our equipment.

A:We are a professional manufacturer for producing fertilizer processing equipment and related machine(fermentation machines,granulator, crusher, mixer, packing, feeding machines and conveyor belt) etc.

2.How should to do if I meet some trouble while using?

A:The English manual book and video will be provide for showing how to resolve the problems, if necessary, we will dispatch our engineer to your factory.

3. Do you provide the installation service after ordering your machines?

A:As for the single machine, we provide the users instruction and operation video.

As for the production line,we provide the professional construction drawing,and arrange the engineer guide the user install the machines.Help the user train the skilled workers.

4.Can we visit your factory to see some fertilizer plant with your machine?

A:We really give every customer a warm welcome to visit our factory,and we can take the customer to visit fertilizer plants with our equipment.

Want to Know more details about this product