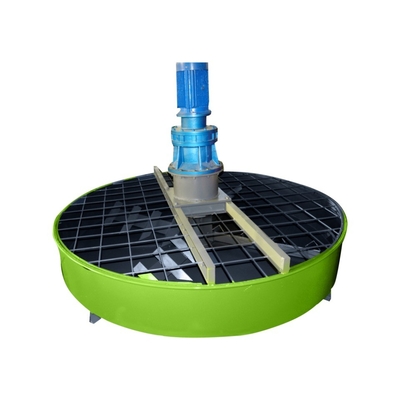

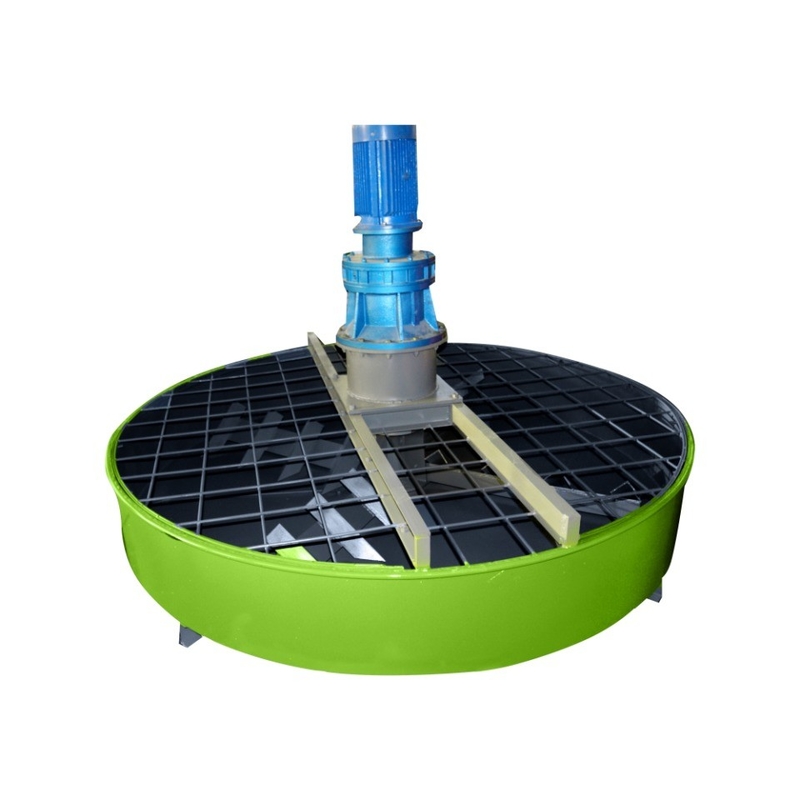

1000L Barrel Volume Fertilizer Vertical Disc Mixer for Optimal Raw Material Mixing

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | YSX |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $800.00/sets >=1 sets |

| Packaging Details: | Compost making machines/ pig/chicken dung/cow manure compost equipment<br>Export package |

| Supply Ability: | 1000 Set/Sets per Month compost equipment |

|

Detail Information |

|||

| Mixer Type: | Rotary | Barrel Volume (L): | 1000 |

|---|---|---|---|

| Material Processed: | Fertilizer | Max. Loading Volume (L): | 1 L |

| Range Of Spindle Speed(r.p.m): | 3 - 5 R.p.m | Max. Loading Capacity: | 1.5m3 |

| Weight (KG): | 1500 KG | Condition: | New |

| Product Type: | BB Fertilizer | Application: | Fertilizer Mixing |

| Voltage: | 380V, 50Hz, 3Phase | Dimension(L*W*H): | Depends On The Model |

| Power (kW): | 35 KW | Warranty: | 1 Year |

| Key Selling Points: | Easy To Operate | Applicable Industries: | Fertilizer Plant |

| Showroom Location: | None | Marketing Type: | Ordinary Product |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 Year | Core Components: | Motor, Pump |

| Product Name: | Fertilizer Vertical Disc Mixer | Keyword: | Fertilizer Vertical Disc Mixer |

| Function: | Mixer Blender | After-sales Service Provided: | Online Support |

| Machine Type: | Dispersion Blender Mixer Machine | Mixing Type: | Electrical Powered Agitator |

| Capacity: | 200L - 5000L Customization | Structure: | Double Jacket |

| Usage: | Mixing Fertilizer | Frequency: | 20KHz |

| Port: | Qingdao, Tianjin, Shanghai | ||

Product Description

Products Description

High efficiency raw material vertical disc mixer for fertilizer processing

Product introduction |

This machine is a new vertical disc mixer, which consists of mixing plate, discharge port, mixing arm, rack, gearbox and transmission mechanism. The characteristic of the machine is that the output shaft end of the reducer drives the stirring main shaft to operate, and the stirring shaft has fixed stirring teeth, and the stirring shaft drives the stirring teeth to mixing the material sufficiently. The mixer has long service life, energy saving, small volume, fast stirring speed and continuous working.The machine is mainly used for the mixing of raw materials. The inside can be lined with polypropylene plate or stainless steel plate. It is not easy to stick material and wear resistance. The cycloid pinwheel reducer make the machine has the characteristics of compact structure, convenient operation, uniform mixing, and convenient discharge and transportation. |

Performance characteristics |

1.High mixing efficiency and less occupied area.The spiral blade adopts high-wear special alloy. 2.The cycloidal gear reducer has the characteristics of compact structure,convenient operation,uniform stirring and convenient unloading etc.The rotation is smooth and the noise is low. 3.The disc mixer feeds material from top,discharge from bottom,which is reasonable. 4.The sealing between each combination surface is tight,so the machine runs smoothly. |

Working principle |

The disc mixer is a new type mixing equipment for continuous running. It is mainly used in organic fertilizer, compound fertilizer and thermal power plant, and can also be used in chemical, metallurgy, mining, building materials and other industries. We adopt special wearing alloy for the spiral blade for longer service time. The disc mixer feeds from the top and discharge from the bottom with reasonable structure. it is widely used in the fertilizer processing industry, and we supply the turn-key basis fertilizer project start from design, producing, installation, debugging and technical training. The electrical motor drives the reducer, and the reducer drives the main shaft, and the main shaft drive the mixing plate to mix the materials. |

Pre-sale Service:

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

4.Training periodically high qualified service technician;

5.Free CAD design: if you can provide the material, your aim capacity and your factory information, we can make a free CAD design for you.

After-sales Service:

1.Highly inspecting equipment in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3.Assisting our clients for foundation construction of equipment;

4.Dispatching engineers to install and debug equipment;

5.Training the first-line operators on site;

6.Regularly visit clients to solve production problems Providing life-long maintenance service;

7.Providing technical exchanging.

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

4.Training periodically high qualified service technician;

5.Free CAD design: if you can provide the material, your aim capacity and your factory information, we can make a free CAD design for you.

After-sales Service:

1.Highly inspecting equipment in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3.Assisting our clients for foundation construction of equipment;

4.Dispatching engineers to install and debug equipment;

5.Training the first-line operators on site;

6.Regularly visit clients to solve production problems Providing life-long maintenance service;

7.Providing technical exchanging.

FAQ

1.Are you manufacturer or trade company?

A:We are a professional manufacturer for producing fertilizer processing equipment and related machine(fermentation machines,granulator, crusher, mixer, packing, feeding machines and conveyor belt) etc.

2.How should to do if I meet some trouble while using?

A:The English manual book and video will be provide for showing how to resolve the problems, if necessary, we will dispatch our engineer to your factory.

3. Do you provide the installation service after ordering your machines?

A:As for the single machine, we provide the users instruction and operation video.

As for the production line,we provide the professional construction drawing,and arrange the engineer guide the user install the machines.Help the user train the skilled workers.

4.Can we visit your factory to see some fertilizer plant with your machine?

A:We really give every customer a warm welcome to visit our factory,and we can take the customer to visit fertilizer plants with our equipment.

A:We are a professional manufacturer for producing fertilizer processing equipment and related machine(fermentation machines,granulator, crusher, mixer, packing, feeding machines and conveyor belt) etc.

2.How should to do if I meet some trouble while using?

A:The English manual book and video will be provide for showing how to resolve the problems, if necessary, we will dispatch our engineer to your factory.

3. Do you provide the installation service after ordering your machines?

A:As for the single machine, we provide the users instruction and operation video.

As for the production line,we provide the professional construction drawing,and arrange the engineer guide the user install the machines.Help the user train the skilled workers.

4.Can we visit your factory to see some fertilizer plant with your machine?

A:We really give every customer a warm welcome to visit our factory,and we can take the customer to visit fertilizer plants with our equipment.

Want to Know more details about this product